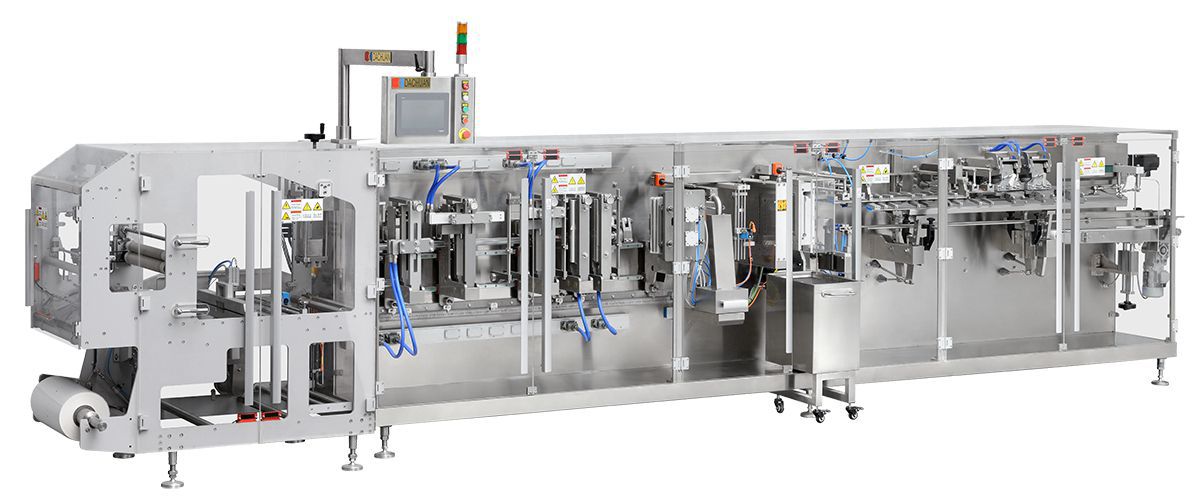

Fully Automatic Horizontal Form Fill Seal Machine, DC-238

The DC-238 HFFS packaging machine is an all-in-one packing tool that makes short work of horizontal film rolling, bag formation, filling and sealing. This ultra-convenient device helps reduce time and waste during production, resulting in the creation of 3-side seal, 4-side seal, stand-up pouch and zipper doypacks. It is suitable for a wide range of applications, from food and daily essentials to medication. And because of its modular structure, it allows for optional coding, molding, sealing, easy-tear and Euroslot seals, meaning customers can opt for the feature most suitable for their needs.

Specifications

| Machine dimensions (L×W×H) | 6760×1450×1945mm |

| Bag width | 75-200mm |

| Bag length | 140×280mm |

| Max. bottom diameter | 100mm |

| Film roll diameter | 550mm |

| Film roll width | 660mm |

| Inner diameter of film roll core | 74mm |

| Bag type | Flat bottom pouch, stand-up pouch, zipper doypack pouch |

| Packing speed | 35-45 bags/min |

| Power | 9.5kW/h |

| Air consumption | 0.5-0.7m³/min |

- This full servo control operation machine offers a total of 6 servo motors that can be adjusted for speed, positioning, and pressure with precision using the touch-screen for added convenience. Intuitive data parameters make operation simple and ensure a consistently reliable performance.

- This horizontal packaging machine is designed with an air pressure system and an enclosed, protective door to reduce the risk of any harm caused by improper use.

- The film roll replacement has been designed with an air expansion shaft, enabling quick and precise changes. The secure installation ensures the roll will remain firmly in place, providing reliability you can trust.

- Its mechanical film drawing system is equipped with a servo motor and a branded photoelectric device. This makes the film drawing positions easier to identify and also compensates for variations in the stretching of the roll-outs, keeping waste to a minimum and ensuring uniform size for the finished product.

- The sealing mold can be automatically adjusted with precise positioning to save time and labor. This adjustment is easy to use and highly accurate, allowing for more convenient and intuitive positioning.

- The utilization of Festo's high-precision solenoid valves and reinforced cylinders in the pneumatic components of the equipment ensures smoother operation, extended part longevity, and minimal wear and tear.

- The sealing results can be twice as good as with low-temperature sealing, ensuring a streamlined and dependable seal; plus, the added edge cooling capability yields finished products with markedly improved edges, more similar to those created with bag-making production, boasting a smooth and secure bond.

- The cutting tool features flat, burr-free edges with the ability to form unique shapes, providing an excellent finish.