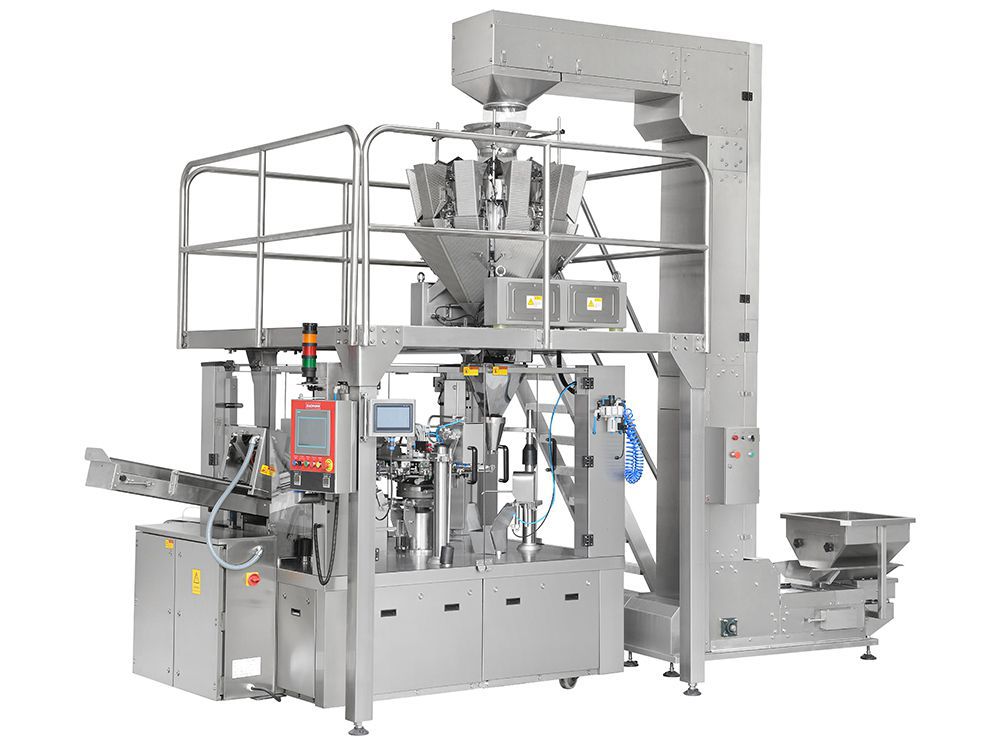

Premade Pouch Packaging Machine, DC-820

-

Applicable pouch width

100-240mm, 240-340mm

-

Applicable pouch length

120-350mm, 80-200mm

-

Packing speed

10-50 bags/min

The DC-820 premade pouch filling and sealing machine is engineered to offer the ultimate in versatility, accommodating liquid, sauce, powder, particles, lumps and more. Equipped with an electronic scale, liquid metering pump, servo screw and bowl-type feeding systems, this machine is capable of automatically filling and sealing an array of bag types. From ordinary stand-up pouches and flat bags (3-side seal bags, 4-side seal bags or back sealing) to special-shaped and zipper bags, this machine offers the best in performance and packaging effect. Working at speeds of 10-50 bags/min, the high speed premade pouch machine is the perfect choice for all your packaging needs.

Specifications

| Model | |||

| Quantity of lanes | Single lane | ||

| Applicable pouch width | 100-240mm | 240-340mm | 100-240mm |

| Applicable pouch length | 120-350mm | 80-200mm | |

| Filling volume | Max. 3L | ||

| Packing speed | 10-50 bags/min | ||

| Applicable pouch type | Stand-up pouch, flat pouch (3-side seal, 4-side seal, back seal), shaped pouch, zipper doypack pouch | ||

| Packaging material | Composite film | ||

- Shorten your turnaround time with the innovative quick size change system. In just ten minutes, speed up any size changing process with this efficient and economical solution.

- The pouch width is conveniently customizable through the touch screen, with a memory function that remembers the pouch size, speed, filling amount, and more.

- Our sealing machine has been uniquely designed to provide perfect sealing - both preheating and pressing. It comes with two sets of hot sealing molds and one set of cold sealing molds; the latter contributing to the formation of flatter sealed pouches and improving the overall quality of the products. Unlike other manufacturers who offer only two sets of hot sealing molds, our machine includes a system which prevents pouch filling and sealing when the pouch is not opened, or when there is no pouches.

- This premade pouch packaging machine is designed with a sound and light alarm system, as well as a feature to take away bags that remain unfilled. With our system, separating the filled from the unfilled bags will no longer be necessary, allowing for more efficient work that does not require stopping and starting.

- This pouch filling and sealing machine consists of imported 304 stainless steel instead of aluminum. The fixtures of the column and turntable included have amazing rust resistance and make it possible to clean the whole product with just a single spray of water.

- Our packaging machine is equipped with an automated lubrication system, meaning there is no requirement to add lubricating oil manually. This significantly reduces labor expenses and makes upkeep simpler.

- Using a machine conveyor belt, your business can benefit from a system that can put hundreds of pouches in at once, drastically increasing efficiency in comparison to other manufacturers who are only capable of putting a limited number of bags in.