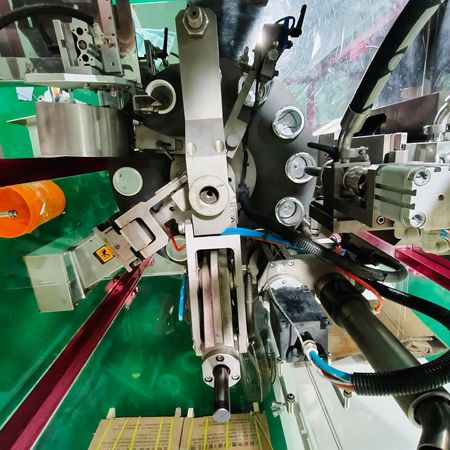

Automatic Tube Filling and Sealing Machine, DC-638-558

-

Filling volume

1-400ml

-

Packing speed

50-70 tubes/min

-

Max. air consumption

4-5kgf/m²

The DC-638-558 tube filler & sealer is a fully automated tube filling and sealing machine capable of working with a multitude of tube sizes, such as plastic, laminated, and 80% of all flat tubes available. It has been designed with easy and fast product specification and pipe length replacement, making it the perfect fit for industries in need of speedy production, such as pharmaceutical, food and daily chemical. Reaching speeds of up to 70 tubes per minute, it's an unbeatable addition to your solution.

Specifications

| Model | DC-638-558 |

| Machine type | Mechanical transmission |

| Machine dimensions (L×W×H) | 2000×1160×2100mm |

| Tube diameter | 13-50mm |

| Tube length | Max. 230mm (including cap) |

| Filling speed | 50-70 tubes/min |

| Power supply | 220/380V,8kW, 3 phase |

| Hopper capacity | 45L (customizable) |

| Applicable tube | Plastic squeeze tube, laminated tube |

-

The feeding mechanism has been enhanced with its filling nozzle upgraded to a lift-operated feeder, enhancing the stability of the feed. This enables materials with excellent fluid properties to be supplied without scattering.

-

The heater of the sealing machine has been updated, allowing for easy adjustment of the height, all without the need for any tool. A negative pressure suction device has also been added, making it easier and simpler to exchange heaters with aluminum-plastic tubes, especially when it comes to plastic tubes and composite tubes.

-

Many modern automatic tube sealing machines don't come with a reverse alarm or stirring feature. However, the storage pipe and lower pipe of the equipment are equipped, allowing you to detect anytime the tube is reversed and allowing you to act immediately.

-

The sealer has been enhanced when it comes to mark identification, making it easy to adjust the seal positioning on the touch screen without having to stop or open the door for manual adjustment. This improved feature enables the mark identification position to be changed in the middle of production, resulting in a more user-friendly experience.

Tube feeding → mark identification → filling → heating → end sealing (code printing) → end cutting → finished product