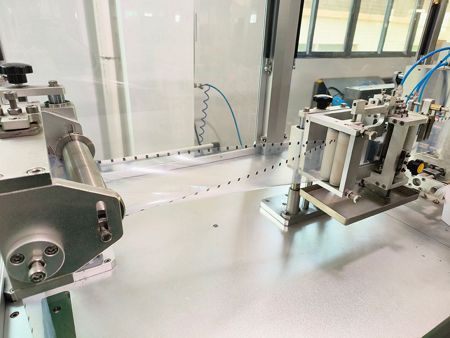

Double Sided Blister Packaging Machine, DC-860

The DC-860 double-sided blister packaging machine is the ideal solution for packing liquids and viscous products. Constructed with thoughtful design and safety considerations, this blister packaging machine is capable of using a plastic film roll to reliably package your materials. Not only does it come with a simpler structure, but it also minimizes the cost of production.

This packaging machine is optimal for packaging, providing a range of possibilities with various materials such as PVC (PE), PET (PE), PVDC and more. Utilization rate of packaging materials is high, with most reaching more than 95% and some even up to 99%.

Specifications

| Machine dimensions (L×W×H) | 2100×1150×1400mm |

| Machine weight | 1400Kg |

| Power supply | 3 phase, 380V, 50Hz |

| Packaging materials | PVC/PE, PET/PE, PVDC, and other laminated films |

| Package size | (0.3-0.4)*240max.(mm) (or depending on mold size) |

| Max. diameter of film roll | Ø 400mm |

| Inner diameter of film roll core | Ø 76mm |

| Blisters per pack | 2-5 blisters/pack (depending on filling dosage) |

| Filling efficiency | 10-20 cycles/min |

| Dosage | 1-20ml |

| Filling accuracy | ≤2%, in compliance with national standards. |

| Forming depth of double-sided blister | 10-20mm |

| Forming depth of single-sided blister | 2-10mm |

- Modular design offers simple machine structure, allows for a swift design cycle, and thus quicker product updates.

- Sturdy architecture, dependable quality, unfailing performance and extended service life.